Yogurt Engineering

Fermented milk, also known as yoghurt, is a product made from fresh cow (sheep) milk or reconstituted milk with or without auxiliary materials and fermented by strains of Lactobacillus bulgaricus and Streptococcus thermophilus. Specifically, it is to inoculate lactic acid bacteria into milk, let it multiply in large numbers at the appropriate temperature (usually 40-42 degrees), and decompose the lactose component in milk into lactic acid. Due to the production of lactic acid, the acidity of the milk fermentation broth gradually decreases. When the pH value reaches about 4.6, the casein in the milk will slowly settle down and form a delicate coagulation. Fermented yogurt needs to be refrigerated at low temperature because it needs to ensure live bacteria.

Classification of fermented milk:

1) According to the different raw materials used, it is divided into: pure yogurt, flavored yogurt, fruit yogurt;

2) According to the different fat content, it can be divided into: full fat, partial degreasing, degreasing and other varieties.

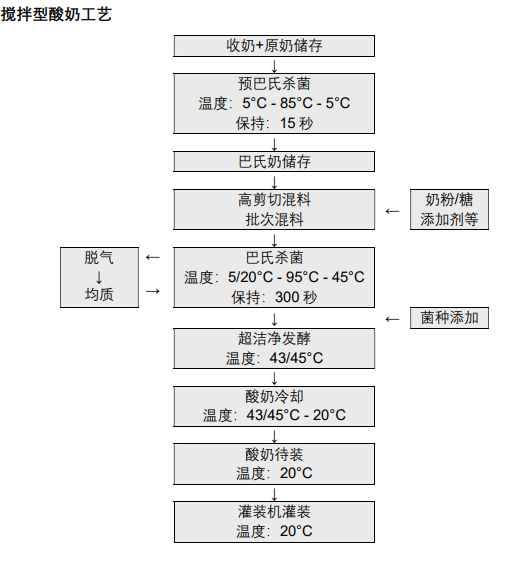

3) According to the different organizational state of the finished product, it can be divided into stirred yoghurt and solidified yoghurt. In short, stirred yoghurt is fermented before filling, and coagulated yoghurt is fermented after filling.

Contact:+86 13651600783

Contact:+86 13651600783

Common processes of yogurt engineering are as follows: